Inventories

At a basic level, a fixed asset is a long term good kept and used by the government, typically over 12 months. An inventory item is also an asset, but is typically kept for less than 12 months, it is intended for distribution (to citizens) or as part of a work in progress to make a good for resale or distribution.

An example of an inventory item is pamphlets, or paper that is purchased to make pamphlets. The pamphlets are intended for distribution to schools. Hence, this is an inventory item. A building, vehicle, or computer is normally considered a fixed asset because it is not intended for distribution (to the public) or as an item for sale by the government. Rather, it is intended for use by the government itself.

The Inventories module allows users to manage inventory items.

Support Entities

Support entities are the back bone of the inventories module and it holds the sourcing package that is a collection of Inventory Items predefined for specific purposes; the advantage for Goods/Services Requests is that this will automatically populate the Goods/Services Request Items that are needed. The Inventory Kardex is the second support entities component which is a view where the user may check all the transactions that have been applied to a particular Inventory Item. Transactions will be displayed in chronological order based on the ‘Inventory Transaction Date'. Third component includes inventory items that are stored as a part of the inventory. This allows the organization to keep all inventory on hand recorded in an organized manner so if individual(s) were looking for an inventory item, they could use this screen to easily retrieve the inventory that they wish to inquire about. The fourth Inventory Item in Court Status Reason states the reasons that will support the ‘Inventory Item in Count’ or ‘Inventory Item in Count Perishable Lot’ Status. It could be used for reporting and statistics.

Inventory Items

Overview

This feature references catalogue items, and contains specific information of the item in an organization, location and warehouse, such as quantity on hand, reorder point, etc.

A screenshot of the Inventory Items feature is available here<. Image is shown as reference material; position and names for labels, fields and buttons are subject to the installed revision, System Parameters and Rendering Control configuration.

Users access Inventory Items from within the menu through this navigation path: Inventories ► Support Entities ► Inventory Items

Visible Fields

The following table lists and describes all visible fields for the Inventory Items, in their default order. Note that some fields depend on System Parameters and Rendering Control configuration to be visible and/or editable by users. Field names are subject to change through language label configuration.

Field | Description |

|---|---|

Application ID | Stores the unique identifier for the inventory items. This is a read only field as the value is automatically generated by the system, and is increased based on a sequence. |

Item | Allows users to select catalogue item from lookup function. |

Warehouse | Represents the physical warehouse where the item is stored. |

Last Count Date | Last date when the item was included in an inventory item count request and when the attribute titled inventory item count request status is equal to Finished. |

Is In Physical Count | This is a read only attribute and can be modified only when a physical count process has been registered. Default value for this field is false. |

Lot Management Required? | System is going to copy the value from attribute titled lot management required from the catalogue item screen. Application users can modify this value. |

Average Unit Cost | The average cost of the item on its standard unit of measure. |

Quantity On Hand | System calculation (users cannot modify this value), updated every time there is an inventory transaction: goods received notes, incoming transfers quantities, subtracting material requests, outgoing transfers quantities, etc. |

| Reserved Quantity | System is going to add here the quantity of the item that are in inventory transfer process to reserve this quantity and decreases the quantity available so this quantity won't be available to be use in other transactions. System sets back to 0.00 this attribute once that the transfer is cancelled or delivered. |

| Available Quantity | This is a read only attribute, represent the available quantity to be use it on any process. |

| Reorder Point | System is going to copy the value from the attribute titled reorder point from the catalogue item screen. |

Order Quantity | System is going to copy the value from the attribute titled order quantity from the catalogue item screen. Application users can modify this value. |

Min Order Quantity | System is going to copy the value from attribute titled 'Min Order Quantity' from the catalogue item screen. Application users can modify this value. |

Maximum On Hand | System is going to copy the value from the attribute titled maximum on hand from the catalogue item screen. Application users can modify this value. |

Inventory Total Cost | System calculation, updated every time there is an inventory transaction processed through the inventory transaction screen. |

| Inventory Turnover | Inventory turnover details how much inventory is sold over a period of time. |

| Days Inventory | Number of inventory days. |

| Last Measuring Warehouse Indicators | Information regarding warehouse indicators. |

Language | Users are allowed to select the language to register the description. |

Remarks | Users are allowed to add relevant information about the item, special treatment, warranty conditions, etc. |

Bar Code | Contains the code recognized by the bar code reader. Mandatory if the parameter titled bar code mandatory is set to true. |

Storage Bin | Users are allowed to select the storage bin from lookup function. |

Location In Warehouse | User defined attribute. It defines the physical location of the item within the warehouse (bid, rack). |

Coding Block | Users are allowed to select the coding block from lookup function. |

Active | Default value for this field is true. If this value is changed to false, such inventory item can't be selected again it remains for references purposes only. |

Perishable Lot Tab | The system populates and updates Perishable Lots information from business transactions (GRN, adjustments) related to the inventory item only when requires lot management flag is true. Application users can see the information but cannot update it. |

Inventory Item Bar Code Alias Tab | This is a collection of bar code aliases associated to a particular inventory item. This is required because the manufacturers may change this code depending on the region or country of manufacture for the same brand/model of a product. |

Buttons

| Button Image | Description |

|---|---|

| The New button allows users to switch to insert mode. This action button allows users to manually create Inventory Items. |

| The Search button allows users to switch to search mode. |

| Find button presents a list of existing items as per the selected filter criteria. From the list users may select one record to retrieve the stored information. |

| Once a record has been created or searched for, users can return to the results screen when necessary. |

| Lookup button allows users to browse and select existing items. Once selected, all available information automatically populates the corresponding fields. |

| The Remove button allows users to remove the selected tab. |

| The Select All button allows users to highlight all the filter criteria. |

| The Unselect All button allows users to unselects all previously highlighted filter criteria. |

| Data Import template button allows users to generate the template file related to the |

| The Import button allows users to Import file. |

| The Save button allows user to save the information inputted. |

Inventory Kardex

Overview

Inventory Kardex is a view where the user may inquire all the transactions, such as Goods Received Notes, Goods Returned Notes, Dispatch Order, Transfer, Adjustment, Initial Inventory, etc. that have been applied to a particular Inventory Item. Transactions will be displayed in chronological order based on the ‘Inventory Transaction Date'.

Navigation

Inventories ► Support Entities ► Inventory Kardex

Inventory Kardex Tab screen Fields

Field | Description |

Inventory Item | The items that are stored as a part of the inventory. |

Description | Short description of the inventory item. |

Unit Of Measure | Classification for measurement of the inventory item. |

Average Unit Cost | The middle (mean /average) cost of the entire inventory items on hand. |

Quantity On Hand | The number of inventory items that is available for use immediately. |

Initial Inventory | The number of early (first) inventory items in stock. |

Sourcing Packages

Overview

A sourcing package is a collection of Inventory Items predefined for specific purposes; the advantage for Goods/Services Requests is that this will automatically populate the Goods/Services Request Items that are needed.

Navigation

Inventories ► Support Entities ► Sourcing Packages

Sourcing Packages screen Fields

Field | Description |

ID | Unique identification code of the Sourcing Package. |

Custom Domain Type | This function creates a Custom Domain Type that can be referenced by any entity within the platform. |

Language | Language used to register the abbreviation and description. |

Abbreviation | Short form of the Sourcing Package. |

Description | Detailed description of the Sourcing Package. |

Sourcing Packages Item

Overview

This tab holds the list of one or more sourcing package item that are part of source package.

Sourcing Packages Item Tab screen Fields

Fields | Description |

Active | Indicates if the Sourcing Package Item is Active. |

Unit of Measure | Select unit of measure to be used for the Sourcing Package Item from Drop Down list. |

Quantity | The quantity of items to be included in the Sourcing Package. |

Item | The Catalogue Item to be included in the Sourcing Package. |

Item in Count Status Reasons

Overview

Inventory Item in Court Status Reason states the reasons that will support the ‘Inventory Item in Count’ or ‘Inventory Item in Count Perishable Lot’ Status. It could be used for reporting and statistics.

Navigation

Inventories ► Support Entities ► Item Count Status Reasons

Item in Count Status Reason screen Fields

Field | Description |

ID | Unique identification code of the Item in Count Status Reason. |

Is Count Status Reason Active | If false, the Item in Count Status Reason is not active. |

Language | Country specific Language used to register short description and description. |

Short Description | Brief description of the Item in Count Status Reason. |

Description | More detailed description of the Item in Count Status Reason. |

Storage Bin

Overview

Storage bin is a storage space or slot. The storage bin is the smallest available unit of space in a Warehouse. The Storage Bin therefore describes the position in the warehouse where the goods are or can be stored. Since the address of a Storage Bin is frequently derived from a coordinate system, a Storage Bin is often referred to as a coordinate.

Navigation

Inventories ► Support Entities ► Storage Bin

Storage Bin screen Fields

Field | Description |

ID | Unique identifier. Automatically generated by the system. |

Row | Field represents the Storage Bin Row value. |

Stack | Field represents the Storage Bin Stack value. |

Level | Field represents the Storage Bin Level value. |

Storage Bin Code | This field is Read Only. Must be the generated by the system. |

Maximum Weight | Field represents the Maximum Weight of the Inventories. Default value is Zero. |

Total Capacity | Field represents the Total Capacity of the Inventories. Default value is Zero. |

Active | Default value is true. If this value is changed to False, such storage bin can't be selected again it remains for references purposes only. |

Default Storage Bin | Default value is False. If this value is changed to True, such storage bin would be the default storage bin for new Inventory Items. Only one Storage Bin could be set as Default Storage Bin per Warehouse. |

Fire Containment Section | Default value is False. If this value is changed to True, the fire containment section is applicable to storage bin. |

Storage Bin Type | These are the possible storage bin types for the storage bin. Possible storage bin types could be Small, Medium and Large. |

Storage Unit Type | These are the possible storage unit types for the storage bin. Possible storage unit types could be Standard European pallet, Standard Industrial pallet, Wire basket or Tank |

Storage Section | Field represents Storage Section ID of Storage Section where the storage bin is located. |

| Warehouse ID | Storage Section Warehouse Id.This value would be assigned automatically by the system. |

Language | Country specific Language used to register description. |

Description | Detailed description of the Storage Bin. |

Storage Section

Overview

Storage Section contains an organizational subdivision of a Storage Type that groups together Storage Bins with similar features for the purpose of putting away stock. The criteria for grouping bins can be defined on a user-individual basis, for example, heavy parts, bulky materials, fast-moving items, slow-moving items. A storage area consists of one or several Storage Bins. The Storage Section can serve as an organizational aid for putting away goods in the warehouse. If user decides on using storage types and storage sections, he must define his organizational goals. Here the physical location is often a decisive organizational factor. It is not absolutely mandatory that user subdivide a storage type into two or more storage sections. However, user must create at least one storage section for each storage type.

Navigation

Inventories ► Support Entities ► Storage Section

Storage Section screen Fields and Tab

Field | Description |

ID | Unique identifier. Automatically generated by the system. |

Active | Default value is True. If this value is changed to False, such storage section can't be selected again it remains for references purposes only. |

Storage Section Code | If parameter Auto generate Storage Section Codes is 'True'. The value is automatically assigned by the system; it’s the value of attribute Storage Section ID. It’s the Read only attribute. If parameter auto generate Storage Section Codes is 'False'. The value is entered manually by the user. It won't be a Read only attribute. |

Storage Section Type | These are the possible storage section types for the storage section. Possible storage section types could be Fastest, Heaviest, Medium demand, Weight, Slowest, Shortest, Lightest, Fluctuating demand |

Storage Type | The user selects only one value. |

| Warehouse ID | Storage Type Warehouse Id, This value would be assigned automatically by the system. |

Language | Country Specific Language used to register description. |

Description | Summary information of the Storage Type. |

Storage Bin Tab | A collection of Storage Bins that belong to this Storage Section displays. It's just display information, if the user wants to delete the bin, it needs to be deleted from the Bin Screen. |

Storage Type

Overview

Storage Type contains a storage area, warehouse facility, or a warehouse zone for Warehouses (Institutions those are used as Inventory Warehouses). Storage Type is a physical or logical subdivision of a warehouse complex that is characterized by its warehouse technique, the space used, its organizational form, or its function. A storage type consists of one or several Storage Sections that consists of one or several Storage Bins.

Navigation

Inventories ► Support Entities ► Storage Type

Storage Type screen Fields and Tabs

Field | Description |

ID | Unique identifier. Automatically generated by the system. |

Active | Default value is true. If this value is changed to False, such storage type can't be selected again it remains for references purposes only. |

Warehouse ID | Institution Code ID of Warehouse where the storage type is located. The user selects only one value. |

Is Goods Receipt Area | Default value is False. If User switches it to True, then this Storage Type is used as Goods Receipt Area. |

Is Goods Storage Area | Default value is true. If User switches it to True, then this Storage Type is used as Goods Receipt Area. |

Is Goods Issue Area | Default value is False. If User switches it to True, then this Storage Type is used as Goods Receipt Area. |

Is Goods Issue Interim Storage Area | Default value is False. If User switches it to True, then this Storage Type is used as Goods Issue Interim Storage Area. |

Is Blocking Indicators and Inventory Procedures | Default value is False. If User switches it to True, then this Storage Type is used as Blocking Indicators and Inventory Procedures. |

Storage Type Code | If parameter Auto generate Storage Section Codes is 'True'. The value is automatically assigned by the system; it is the value of attribute Storage Type ID. It is a Read only attribute. If parameter Auto generate Storage Section Codes is 'False'. The value is entered manually by the user. It won’t be a Read only attribute. |

Language | Country Specific Language used to register name and description. |

Name | Field represents the Storage Type name. |

Description | Field represents the detailed description of the Storage Type. |

Storage Sections Tab | A collection of Storage Sections that belong to this Storage Type displays. No Add or remove Section in it. It's just display information, if the user wants to delete the section, it needs to be deleted from the Section Screen. |

Inventory Adjustment

Overview

An inventory adjustment would be processed to register any changes or differences among stock quantities in a given warehouse. The reason for such an adjustment could be to enter any variances of stock quantities based on the results of periodic stock taking. This functional section is used for that reason and also used to enter the opening balances of the existing stocks at the beginning of using the system.

This screen represents a transaction that affects the Inventory Items for a particular Warehouse based on differences in a stock taking process or due to a fortuitous event (accidental loss, damage, etc.). The reason for adjustments is to keep the consistency between the 'physical' and the 'on books' Inventory.

Navigation

Inventories ► Inventory Adjustment

Inventory Adjustment screen Fields and Tab

Field | Description |

ID | A unique value that is automatically generated by the system. |

| Fiscal Year | Fiscal Year when this voucher is created. Automatically assigned by the system with current fiscal year. If user has access to post transactions to prior periods, system will allow user to post a transaction to prior fiscal year (never to future fiscal year) as long as the selected fiscal year is not fully closed. |

| Fiscal Period | Fiscal Period when this voucher was created. Automatically assigned by the system with the current fiscal period. If user has access to post transactions to prior periods, system will allow user to post a transaction to prior period (never to future periods) as long as the selected period belongs to the fiscal year mentioned above and also it is closed for regular transactions (not fully closed) |

| Workflow Status | Workflow Status of the Inventory Adjustment. |

| Origin | Origin of the Inventory Adjustment. Possible values are: MANUAL (default), when user creates the adjustment on the entity DATA IMPORT, when user creates the adjustment using data import tool INVENTORY COUNT REQUEST, when system creates the adjustment automatically from an inventory count reques. This attribute is automatically populated by the system. |

Is Automatic Adjustment | For viewing purposes only. If selected, Automatic Adjustment specifies if this transaction has been issued automatically by a process, or if NOT selected, inventory adjustment has been entered manually by a user. |

Effective Date | Effective date applicable for this transaction. |

Warehouse | It represents the physical warehouse where the item is stored. |

| Journal Voucher | Automatically populated by the system when Inventory adjustment creates a Journal voucher |

Employee | Name of the person that is the intervenient in this transaction. |

Inventory Item Count Request | Contains the general information for the Inventory Item Count. |

Adjustment Type | Choose from either "Initial Inventory" or "Quantity. |

Language | Country Specific Language used to register reason. |

Reason | A brief reason for this transaction. |

Inventory Adjustment Item Tab | Information on the Inventory Item used in the adjustment. |

Inventory Adjustment Item

Overview

Field | Description |

ID | Automatically or manually generated unique identification code, depending on parameter setup. |

Inventory Item | Field represents the Inventory Item to be adjusted |

New Quantity on Hand | Change in quantity for the Item. |

Quantity Charge | Difference between values (calculated automatically). |

Unit Cost | Cost per unit prior to adjustment. |

New Unit Cost | Cost per unit after adjustment. |

Value Change | Difference between values (calculated automatically). |

Inventory Adjustment Item Perisable Lots Tab | A collection of zero or more quantities to be adjusted on one or more Perishable Lots. Detailed information for the Perishable Lot of the inventory item being adjusted. |

Inventory Adjustment Item Perishable Lot

Overview

A collection of zero or more quantities to be adjusted on one or more Perishable Lots. Detailed information for the Perishable Lot of the inventory item being adjusted.

Inventory Adjustment Item Perishable Lots Tab Fields

Field | Description |

Code | Unique, system generated code that serves as the identifier for the perishable lot. |

Production Date | The date on which the perishable lot was produced. |

Expiration Date | The date on which the perishable lot is expected to expire. |

Quantity on Hand | The amount of items ‘on hand’, encompassing the lot. |

Received Quantity | The quantity received. |

Language | Country Specific Language used to register remarks. |

Remarks | Any details on the inventory adjustment. |

Manufacturer Lot Id | The identification of the manufacturer’s lot. |

Inventory Item Count Request

Overview

Inventories in an organization are constantly changing because of the many different processes being implemented throughout different departments. It is important for each department to keep track of these changes in order to have an accurate outlook on future inventory quantities. This section of the system is a tool for keeping count of the Inventory stock. The system will do a unique inventory item count depending on the specific search criteria such as Institution, Location, Warehouse, Item Class, etc. Each inventory count is requested and recorded using a unique code. This screen contains and displays all the details of each listed count request. It also displays, in two other separate sections, the employees who have access to do an inventory count and displays the item(s) that are being processed in the inventory item count. The inventory item count request will display the information of a Count request and the result of its physical count.

Navigation

Inventories ► Count Requests

Inventory Item Count Request screen Fields and Tab

Field | Description |

ID | Unique Code that identifies the Inventory Item Count Request. This is automatically populated by the system. |

| Fiscal Year | Fiscal Year when this voucher is created. Automatically assigned by the system with current fiscal year. If user has access to post transactions to prior periods, system will allow user to post a transaction to prior fiscal year (never to future fiscal year) as long as the selected fiscal year is not fully closed. |

| Fiscal Period | Fiscal Period when this voucher was created. Automatically assigned by the system with the current fiscal period. If user has access to post transactions to prior periods, system will allow user to post a transaction to prior period (never to future periods) as long as the selected period belongs to the fiscal year mentioned above and also it is closed for regular transactions (not fully closed) |

| Workflow Status | Workflow status of the Inventory Item Count Request. |

Count Request Start Date | Date when the Inventory Item Count Request was saved. By Default - the current date automatically appears. |

Request Responsible Employee | The employee that is responsible for the Inventory Item count taking. |

Organization | Contains the information of every Institution Unit that plays a role in the system as budget office, as inventory or asset warehouse, purchase office, etc. |

Language | Country Specific Language used to register abbreviation and description. |

Abbreviation | Short Description for the Inventory Item Count Request. |

Description | Description for the Inventory Item Count Request. |

Users Allowed During Inventory Count Tab | Collection of one to more employee who are allowed to add and/or modify ‘Inventory Items’. |

Inventory Item in Count Tab | Collection of one to more ‘Inventory Item’ in count request. |

Inventory Transaction

Overview

This screen contains general information of all Inventory Items transactions. It cannot be populated by a direct manual process and will be affected only by the transactional processes.

All Inventory Transaction Types, such as: Transfer, Dispatch Order, Goods/Services Received/Returned Note, Warehouse Returned Note, Adjustment once approved in its own screen, are available for inquire in Inventory Transactions that transaction will be populated in the Inventory Transaction screen. Users will be able to search these transactions and view them in the Inventory Transaction screen.

Navigation

Inventories ► Inventory Transactions

Inventory Transaction screen Fields and Tabs

Field | Description |

ID | Unique Code that identifies the Inventory Transaction. This is automatically populated by the system. |

Reference Document | Reference to the document ID from the original transaction. It can be a Goods Received/Return Notes, Dispatch Order, Transfer, and Adjustment. |

Transaction Type | This attribute can take one of the following values, these are Transfer, Dispatch Order, Goods/Services Received/Returned Note, Warehouse Returned Note, and Adjustment. |

Item | The value for this attribute are copied from the attribute titled Catalogue Item from the Inventory Item screen. |

Warehouse | The value for this attribute are copied from the attribute titled Warehouse from the Inventory Item screen. |

Inventory Item | Reference to the Inventory Item. |

Quantity In | Copied from the 'Quantity' attribute on the 'Reference Document' related to the Inventory Item. This field is mandatory when the attribute titled 'Quantity Out' does not have a value. |

Quantity Out | Copied from the ‘Quantity’ attribute on the 'Reference Document' related to the Inventory Item. This field is mandatory when the attribute titled 'Quantity In' does not have a value. |

Unit Cost | Copied from the ‘Unit Cost’ attribute on the 'Reference Document' related to the Inventory Item |

Quantity Available | System calculation. Default value is the same as the attribute titled ‘Quantity In’ or the attribute titled ‘Quantity Out’ and it is updated every time that an Inventory Transaction with the attribute titled ‘Quantity Out’ has been registered (in the Inventory Transaction Screen). Mandatory when there is a value in the attribute titled ‘Quantity In’ and when the attribute titled ‘Inventory Item Costing Method’ is set to be either ‘FIFO’ or ‘LIFO’ in the Inventory Item screen |

Total Amount | This field is a system calculation. It uses the following two formulas depending on the situation 1) If there is a value in the attribute titled ‘Quantity In’ Quantity in Value X Unit Cost Value and 2) If there is a value in the attribute titled ‘Quantity Out’ Quantity out Value X Unit Cost Value. |

AVG Cost After Transaction | Copied from the attribute titled 'Average Unit Cost' from the Inventory Item screen. It is referenced after the process of updating the Inventory Item has been performed and only when the attribute titled ‘Inventory Item Costing Method’ is set equal to ‘Weight Average’. |

Qty on Hand before Transaction | The value for this field is copied from the attribute titled 'Quantity On Hand' from the Inventory Item screen. It represents the quantity on hand before the process of Updating the Inventory Item has been performed. |

Transaction Details Tab | Applicable when this is an 'OUT' transaction and Catalogue Item Costing Method is 'FIFO' or 'LIFO'. This collection is populated by the system automatically. |

Perishable Lot Tab | Collection of zero or more Inventory Transaction Perishable Lots. Applicable when Inventory Item requires Lot Management. This is a copy of the Perishable Lot Quantity specified in the Detail Transaction Entity. |

Inventory Transfer/Return

Overview

An Inventory Transfer/Return is a transaction that allows transferring goods from one warehouse to another; this has impact on partial Warehouse Inventories but doesn't affect the Global Inventory. The system allows only Single Warehouse to Warehouse operations, which means that no multiple destinations are allowed from a single source warehouse. A journal voucher issue’s only if the Catalogue Item Class Coding Block is different from the source Warehouse Catalogue Item to the destination Warehouse Catalogue Item.

Navigation

Inventories ► Inventory Transfer/Returns

Inventory Transfer/Returns screen Fields and Tab

Field | Description |

ID | Unique Code that identifies the Inventory Transfer/Return. This is automatically populated by the system. |

| Fiscal Year | Fiscal Year when this voucher is created. Automatically assigned by the system with current fiscal year. If user has access to post transactions to prior periods, system will allow user to post a transaction to prior fiscal year (never to future fiscal year) as long as the selected fiscal year is not fully closed. |

| Fiscal Period | Fiscal Period when this voucher was created. Automatically assigned by the system with the current fiscal period. If user has access to post transactions to prior periods, system will allow user to post a transaction to prior period (never to future periods) as long as the selected period belongs to the fiscal year mentioned above and also it is closed for regular transactions (not fully closed) |

Workflow Status | Depending on the Workflow Configuration Setting for this Entity the basic Stages are Created, Approval Requested, Approved, Void, Closed, Cancelled, Acknowledged. Default value is created. It is user defined status. |

| Created On | Creation date of the Inventory Transfer/Return. |

Is Transfer | Specifies if this Transfer/Return is for Transfer or Return. |

Created on | Current system date updated by system. |

Estimated Delivery | The estimated date of arrival to the destination warehouse, the system assigns by default the ‘Reason for Transfer’ value however users may change this value according to a reasonable estimated date. |

Delivery on | This attribute must be updated by the system once the shipping method has been set to 'Delivered'. |

Shipping Method | This field can take one of the following values 'Pickup at Source Location', 'Transport to Destination'. Shipping method is a value used to classify how the return or transfers take place. By Default - 'Transport to Destination' is displayed. |

Transfer Return Priority | This field can take one of the following values 'Low', 'Normal', 'High'. By Default - 'Normal' is displayed. This field is used to bring attention the importance of the Transfer. |

Delivered By | The employee who delivered the inventory transfer/return. |

Dispatched By | The employee who releases the inventory transfer/return. |

Received By | The employee who received the inventory transfer/return. |

Source Institution | The warehouse where the items outgoing or the Institution that is returning the goods. |

Destination Warehouse | The warehouse where the items are incoming. |

Language | Country Specific Language used to register description and remarks. |

Description | Information pertaining to the transfer. This usually includes an explanation of its use and objectives. |

Remark | More information related to this transfer considered relevant. |

Inventory Transfer Return Item Tab | A collection of one or more Inventory Transfer/Return Items. |

| Attachment Tab | Additional files related to the Inventory Transfer/Return Items. |

Attachments Tab

Overview

System allows to attach files to support theInventory Transfer / Return process.

Attachments screen Fields

| Field | Description |

| Id | Consecutive number auto generated by the system. It will be unique within the system. |

| Language | Country specific language for the title and description. |

| Title | Title of the Attachments. |

| Description | Description of the attachments. |

| Attachment | System allow to selete and upload supporting file. File type can be: pdf, doc, xls, jpg, etc. |

| Date Time | Date and Time of the last operation performed on the attachment document. Visible for the user. Automatically assigned by the system. |

| User | Last user who uploaded or updated the document. Visible for the user. Automatically assigned by the system. |

| Language | Mandatory field, language of the document. The system will suggest the default language; however the user can change such language. |

Inventory Transfer Return Item

Overview

This tab holds details information about inventory item transfer or return.

Inventory Transfer Return Item Tab screen Fields and Tabs

Field | Description |

Inventory Item | This field contains the detail of the Items in a specific Organization, Location and Warehouse. |

Quantity | The quantity of the inventory item to be transferred/returned to the destination warehouse. |

Quantity Transferred Returned | The value is automatically updated by system as per quantity available in mentioned Inventory Item. |

Unit Cost | This field is automatically generated by the system. Unit Cost is based on the Costing Method associated to the particular Inventory Item. |

Total Item Cost | This field is automatically generated by the system. This is the total amount for the item quantity and unit cost. This attribute is useful when FIFO/LIFO costing method is being used since this Unit Cost can have slight variations especially when the cost has been taken from different "in" transactions. |

Inventory Return Item Dispatch Order Tab | Information on the order for returning inventory goods. |

Inventory Transfer Return Item Perishable Lot Tab | Information on the perishable lot for the Items used in the return or transfer. |

Inventory Return Item Dispatch Order

Overview

Collection of Inventory Return Item Dispatch Order details

Inventory Return Item Dispatch Order Tab screen Fields

Field | Description |

Dispatch Order | This is the field that supports the inventory-out from a particular warehouse in order to supply the goods requested by a Goods/Services Request. |

Quantity | The quantity to be returned for this particular Dispatch Order |

Unit Cost | A system generated calculation. This field represents the Unit Cost of the Dispatch Order that is being returned. |

Return Item Dispatch Order Perishable Lot Tab | Information on the perishable lot for the Item(s) used in the Dispatch Order. |

Reports

Overview

Inventory Reports are used to monitor and manage the processes involved with the inventory items currently being stored at the warehouse. These reports will manage when to purchase new inventory items, the capacity at the warehouse, and can help to improve the efficiency of the processes used for inventory management.

Inventory Reports can perform these functions:

- Classifies inventories by user-designated groups, with subtotaling and totaling of an overall value

- Provides standard governmental reporting: i.e., it should not include information such as investment tax credit data or basis costs

- Tracks all transactions affecting the value of inventories by the original source document number and date, and the module and application in which the transaction originated

- Displays or print subsidiary ledgers of fixed inventory balances

- Produces a transaction register audit trail of all acquisitions, transfers, changes, retirements, and disposals during a user-defined time period by inventory type, department, transaction date, funding source, or purchase amount

- Provides a money total of fixed inventory purchases by their funding source and department/organization

- Provides a vendor/PO listing of inventories by vendor or in purchase order number sequence

- Produces a deletion report showing items by inventory type which have physically been disposed of but still remain on file for information purposes

- Produces a forecast of assets and inventories scheduled for replacement, based on user-specified criteria, such as useful life, scheduled disposition date, or odometer readings

- Allows reporting and inquiry of replacement cost by department or organization unit and by inventory type

- Prints reports to support taking of physical inventory by division and/or location

Below you will find a list of all Inventory Reports used during the Inventory Management Process.

Inventory Catalogue Report

Overview

This report shows the complete repository of Inventory Items. It contains information of each Inventory Item such as ID, Short Description, Bar Code, Quantity on Hand, Unit of Measure, Warehouse ID, Last Acquisition Date, etc.

It includes the General List of Items by Institution grouped by Class, by Category, and by Warehouse.

Some filters are available such as Warehouse, Item Class, Item Category, etc.

Navigation

Inventories ► Reports ► Inventory Catalogue

Inventory Catalogue Report screen Fields

Field | Description |

Group By | Indicates how the items within the report is grouped, either ‘Institution’ or ‘Item Class’. |

Institution | Users can look up and select an Institution as filter criteria for the Inventory Catalogue Report. |

Warehouse | Users can look up and select a Warehouse as filter criteria for the Inventory Catalogue Report. |

Item Class | Users can look up and select an Item Class as filter criteria for the Inventory Catalogue Report. |

Item Category | Users can look up and select an Item Category as filter criteria for the Inventory Catalogue Report. |

Bar Code | A bar code can be entered as filter criteria for the Inventory Catalogue Report. |

Lot Management Required | If checked indicates that lot management is required. |

From Date | Beginning limit of the last count for the inventory items covered in the report. |

To Date | End limit of the last count for the inventory items covered in the report. |

From Date | Beginning limit of the last acquisition for the inventory items covered in the report. |

To Date | End limit of the last acquisition for the inventory items covered in the report. |

| Sort By | Click the "Move selected Item" or "Move All Item" icons to add and remove filter criteria to / from the selected list and click the "Up Arrow", "Down Arrow" icons to move the items in the selected list up and down to put them in the desired order of appearance. |

Item Listing Report

Overview

This report shows a list of the Inventory Items within an Institution. It contains information of each Inventory Item such as Catalogue Item ID, Item Short Description, Item Class, Item Category, Last Vendor ID, Warehouse ID, Quantity on Hand, Average Cost, Total Cost, etc. Some filters are available such as Warehouse, Last Vendor, Item Class, and Item Category.

Navigation

Inventories ► Reports ► Item Listing

Inventory Item Listing Report screen Fields

Field | Description |

Institution | Users can look up and select an Institution as filter criteria for the Item Listing Report. |

Warehouse | Users can look up and select a Warehouse as filter criteria for the Item Listing Report. |

Last Vendor | Users can look up and select a Last Vendor as filter criteria for the Item Listing Report. |

Item Class | Users can look up and select an Item Class as filter criteria for the Item Listing Report. |

Item Category | Users can look up and select an Item Category as filter criteria for the Item Listing Report. |

Add More Columns | Click the "Move selected Item" or "Move All Item" icons to add extra coulmn in this report. |

Sort By | Click the "Move selected Item" or "Move All Item" icons to add and remove filter criteria to / from the selected list and click the "Up Arrow", "Down Arrow" icons to move the items in the selected list up and down to put them in the desired order of appearance. |

Catalogue Item ID | By the preferred ascending and descending order using the Red Arrow icons. |

Inventory Item Count Request Worksheet Report

Overview

The Inventory Item Count Request Worksheet Report shows the Inventory Items and its corresponding Perishable Lots pertaining to an Inventory Item Count Request, this report will be used during the physical inventory stock take process. It contains information of each Inventory Item such as ID, Description, Unit of Measure, etc. Some of the columns defined in this report will not contain information so the person in charge of the stock take uses such blank spaces to take notes of the quantities actually found.

Navigation

Inventories ► Reports ► Inventory Item Count Request worksheet Report

Inventory Item Count Request Worksheet Report screen Fields

Field | Description |

Inventory Item Count Request | Users can look up and select an Inventory Item Count Request for the Inventory Item Count Request Worksheet Report. |

Institution | Users can look up and select an Institution as filter criteria for the Inventory Item Count Request Worksheet Report. |

Inventory Item | Users can look up and select an Inventory Item as filter criteria for the Inventory Item Count Request Worksheet Report. |

Item Class | Users can look up and select an Item Class as filter criteria for the Inventory Item Count Request Worksheet. |

Sort By | Click the "Move selected Item" or "Move All Item" icons to add and remove filter criteria to / from the selected list and click the "Up Arrow", "Down Arrow" icons to move the items in the selected list up and down to put them in the desired order of appearance. |

Item Tracking Report

Overview

This report displays the complete tracking (inputs and outputs) of an Inventory Item within a Warehouse, including Transaction Date, Transaction Type, Reference Document ID, Input Quantity, Input Amount, Output Quantity, Output Amount, Balance Quantity, and Balance Amount.

Navigation

Inventories ► Reports ► Item Tracking

Item Tracking Report screen Fields

Field | Description |

Institution | Users can look up and select an Institution as filter criteria for the Item Tracking Report. |

Inventory Item | Users can look up and select an Inventory Item as filter criteria for the Item Tracking Report. |

Transaction Type | The report may be filtered by the Transaction Type of the item. Zero, one or more than one type may be selected. |

From Date | Beginning limit for the transaction date covered in the report. |

To Date | End limit for the transaction date covered in the report. |

Catalogue Item ID | By the preferred ascending and descending order using the Red Arrow icons. |

Item Count Variances Report

Overview

This report displays Inventory Items and corresponding Perishable Lots pertaining to an Inventory Item Count Request with quantity and amount variances. This report is used during the physical inventory stock taking process. Some filters are available such as Inventory Item Count Request ID, Item Class, and Item ID.

Navigation

Inventories ► Reports ► Item Count Variances

Item Count Variances Report Filter Fields

Field | Description |

Is Automatically Reconciled | If checked indicates that the report is filtered according to the automatic reconciliation attribute. |

Inventory Item Count Request | Users can look up and select an Inventory Item Count Request as filter criteria for the Item Count Variances Report. |

Item Class | Users can look up and select an Item Class as filter criteria for the Item Count Variances Report. |

Inventory Item | Users can look up and select an Inventory Item as filter criteria for the Item Count Variances Report. |

Location in Warehouse | Enter a description for the inventory items location in warehouse. |

Sort by | Click the "Move selected Item" or "Move All Item" icons to add and remove filter criteria to / from the selected list and click the "Up Arrow", "Down Arrow" icons to move the items in the selected list up and down to put them in the desired order of appearance. |

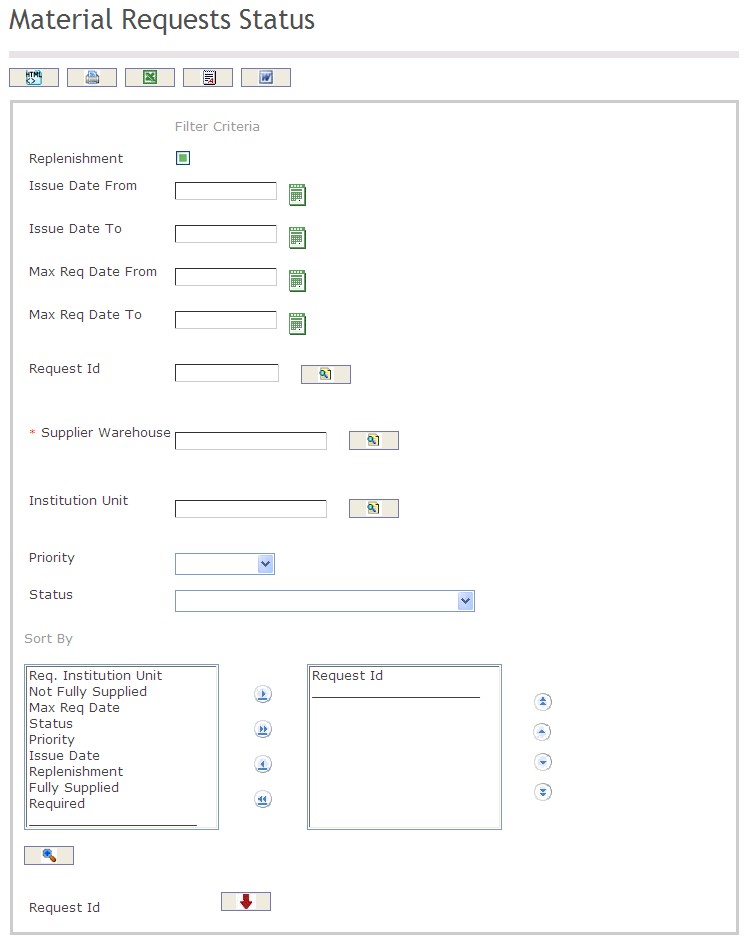

Item Requisitions Report

Overview

This report displays a list of requests for an Inventory Item within a Warehouse. It contains information on the details of each request such as Request ID, Issue Date, Required Quantity, Total Cost, Supply Status, Purchase Requisition Ref, Priority, and Maximum Required Date.

Navigation

Inventories ► Reports ► Item Requisitions

Item Requisitions Report Filter Fields

Field | Description |

Warehouse | Users can look up and select a Warehouse as filter criteria for the Item Requisitions Report. |

Inventory Item | Users can look up and select an Inventory Item as filter criteria for the Item Requisitions Report. |

Request ID | Users can look up and select a Request ID as filter criteria for the Item Requisitions Report. |

Register Employee | Users can look up and select a Registered Employee as filter criteria for the Item Requisitions Report. |

Reception Employee | Users can look up and select a Reception Employee as filter criteria for the Item Requisitions Report. |

Supply Status | Filter Criteria to filter the report by the supply status of the inventory items, |

Priority | Filter the report by the priority placed on the inventory item requisition. |

Request Group | Filter Criteria to filter the report by request group. |

Is Replenishment Request | If checked indicates that the report is filtered according to the Replenishment Request attribute. |

Is Purchase Requisition | If checked indicates that the report is filtered according to the Purchase Requisition attribute. |

Purchase Requisition | Users can enter purchase requisition information to filter the report by. |

Issue Date | Users can use begging issue date in the Form Date field and End issue Date in the To Date field to generate report between the beginning and ending date. |

Max Reg Date | Defines the maximum date for a requisition to take place. |

Sort by | Click the "Move selected Item" or "Move All Item" icons to add and remove filter criteria to / from the selected list and click the "Up Arrow", "Down Arrow" icons to move the items in the selected list up and down to put them in the desired order of appearance. |

Items in Reorder Point Report

Overview

This report displays a list of Inventory Items in Reorder Point within an Institution. The reorder point of a given item refers to the moment when it reaches the level of quantity within a warehouse that requires its stock to be replenished. This report contains information of each Inventory Item such as Catalogue Item ID, Warehouse, Unit of Measure, Warehouse Section, Quantity on Hand, Reorder Point, Order Quantity, Minimum Order Quantity, Maximum on Hand, Remarks, and Last Perishable Lot ID.

Navigation

Inventories ► Reports ► Items in Reorder Point

Items in Reorder Point Report Filter Field

Field | Description |

Institution | Users can look up and select an Institution as filter criteria for the Items in Reorder Point Report. |

Warehouse | Users can look up and select a Warehouse as filter criteria for the Items in Reorder Point Report. |

Last Perishable Lot Id | Users can look up and select a Last Perishable Lot Id as filter criteria for the Items in Reorder Point Report. |

Add More Columns to Report | Click the “Move Selected Item”, “Move All Item”, “Remove Selected Item”, “Remove All Item” icons to add extra column in this report. |

Sort By | Click the “Move Selected Item”, “Move All Item”, “Remove Selected Item”, “Remove All Item” icons to add and remove filter criteria to / from the selected list and click the “Move Selected Item to Top of List”, “Move Selected Item up one in List”, “Move Selected Item down one in List”, “Move Selected Item to Down of List” icons to move the items in the selected list up and down to put them in the desired order of appearance. |

Catalogue Item ID | By the preferred ascending and descending order using the Red Arrow icons. |

Item Detailed Information

Overview

The Item Detailed Information Report displays the detailed information for an Inventory Item.

Navigation

Inventories ► Reports ► Item Detail Information

Item Detailed Information Report Filter Field

Field | Description |

Catalogue Item | Users can look up and select a catalogue item as filter criteria for the Item Detailed Information Report. |

Expired Items Report

Overview

Expired Items report shows a list of Items expired or soon to expire within a Warehouse. It contains information of each Inventory Item such as Catalogue Item ID, Item Short Description, Bar Code, Perishable Lot ID, Expire Date, Quantity on Hand, Average Unit Cost, Total Cost, etc.

Some filters are available such as Expiring Options (Expired Items, to expire in the next week, to expire in the next month, expire dates range), Catalogue Item ID, Bar Code, and Perishable Lot ID.

Navigation

Inventories ► Reports ► Expired Items

Expired Items Report Filter Fields

Field | Description |

Warehouse | Users can look up and select a Warehouse as filter criteria for the Expired Items Report. |

Expiring Items | Filter the report by the status of expiring items. |

Expire From Date | Beginning limit for the “expire date” covered in the report. |

Expire To Date | End limit for the “expire date” covered in the report. |

Catalogue Item Id | Users can look up and select a Warehouse as filter criteria for the Expired Items Report. |

Bar Code | Filters the report by the barcode for the expired items. |

Perishable Lot Id | Users can look up and select a Warehouse as filter criteria for the Expired Items Report. |

Sort By | Click the “Move Selected Item”, “Move All Item”, “Remove Selected Item”, “Remove All Item” icons to add and remove filter criteria to / from the selected list and click the “Move Selected Item to Top of List”, “Move Selected Item up one in List”, “Move Selected Item down one in List”, “Move Selected Item to Down of List” icons to move the items in the selected list up and down to put them in the desired order of appearance. |

Expire Date | By the preferred ascending and descending order using the Red Arrow icons. |

Perishable Lots Report

Overview

This report displays information related to Perishable Lots of an Inventory Item. Perishable lots are those that have an expiration that that must be taken into consideration when managing the inventory stock.

Navigation

Inventories ► Reports ► Perishable Lots

Perishable Lots Report Filter Fields

Field | Description |

Item | Users can look up and select an Item as filter criteria for the Perishable Lots Report. |

Perishable Lot Id | Users can look up and select a Perishable Lot Id as filter criteria for the Perishable Lots Report. |

| Warehouse | Users can look up and select a Warehouse as filter criteria for the Perishable Lots Report. |

Expire Date | Users can use begging expire date in the Form Date field and End issue Date in the To Date field to generate report between the beginning and ending date. |

Production Date | Users can use begging and end date that the inventory item was produced (manufactured). |

Sort By | Click the “Move Selected Item”, “Move All Item”, “Remove Selected Item”, “Remove All Item” icons to add and remove filter criteria to / from the selected list and click the “Move Selected Item to Top of List”, “Move Selected Item up one in List”, “Move Selected Item down one in List”, “Move Selected Item to Down of List” icons to move the items in the selected list up and down to put them in the desired order of appearance. |

Expire Date | By the preferred ascending and descending order using the Red Arrow icons. |

Warehouse In/Out (Operational) Report

Overview

This report displays the list of inventory moving in and out of a Warehouse (item transfers, etc.). It contains information about every transaction such as Transaction Date, Transaction Type, Transaction Document ID, Inventory Item, Input Quantity, Input Amount, Output Quantity, Output Amount, Balance Quantity, and Balance Amount.

Navigation

Inventories ► Reports ► Warehouse In/Out (Operational)

Warehouse In/Out (Operational) Report Filter Fields

Field | Description |

Warehouse | Users can look up and select a Warehouse as filter criteria for the Warehouse In/Out (Operational) Report. |

Catalogue Item | Users can look up and select a Catalogue Item as filter criteria for the Warehouse In/Out (Operational) Report. |

Transaction Type | The report may be filtered by the Transaction Type of the item. Zero, one, or more than one type may be selected. |

Transaction Date | Users can use begging and end date that the Inventory Transaction was registered. |

Sort By | Click the “Move Selected Item”, “Move All Item”, “Remove Selected Item”, “Remove All Item” icons to add and remove filter criteria to / from the selected list and click the “Move Selected Item to Top of List”, “Move Selected Item up one in List”, “Move Selected Item down one in List”, “Move Selected Item to Down of List” icons to move the items in the selected list up and down to put them in the desired order of appearance. |

Transaction Date | By the preferred ascending and descending order using the Red Arrow icons. |

Warehouse In/Out (Accountability) Report

Overview

This report displays the list of inventory movement (in and out of warehouses, based on needs or transactions) grouped by Coding Block within a Warehouse. It contains information about every transaction such as Transaction Date, Transaction Type, Transaction Document ID, Input Amount, and Output Amount.

Navigation

Inventories ► Reports ► Warehouse In/Out (Accountability)

Warehouse In/Out (Accountability) Report Filter Field

Field | Description |

Warehouse | Users can look up and select a Warehouse as filter criteria for the Warehouse In/Out (Accountability) Report. |

Coding Block | Users can look up and select a Coding Block as filter criteria for the Warehouse In/Out (Accountability) Report. |

Transaction Document Id | Filters the report by the Transaction Document Id if entered. |

Transaction Type | The report may be filtered by the Transaction Type of the item. Zero, one, or more than one type may be selected. |

Transaction Date | Users can use begging and end date that the Inventory Transaction was registered. |

Sort By | Click the “Move Selected Item”, “Move All Item”, “Remove Selected Item”, “Remove All Item” icons to add and remove filter criteria to / from the selected list and click the “Move Selected Item to Top of List”, “Move Selected Item up one in List”, “Move Selected Item down one in List”, “Move Selected Item to Down of List” icons to move the items in the selected list up and down to put them in the desired order of appearance. |

Coding Block | By the preferred ascending and descending order using the Red Arrow icons. |

Transaction Date | By the preferred ascending and descending order using the Red Arrow icons. |

Tag Barcodes Of Inventory Items Report

Overview

Display report for tag of the bar code corresponding to the Inventory Item.

Navigation

Inventories ► Reports ► Tag Barcodes of Inventory Items Report

Tag Barcodes of Inventory Items Report Filter Fields

Field | Description |

Type of Barcode | Field represents the bar code type of inventory. |

Warehouse | Warehouse ID where the Inventory Items are stored. Optional parameter. |

Item Class Stack | Inventory Item could belong to a Catalogue Item, also a Catalogue Item could belong to an Item Class. Optional parameter. |

Catalogue Item | Catalogue Item ID of the Inventory Item. Optional parameter. |

Catalogue Item Category | Inventory Item could belong to a Catalogue Item, also a Catalogue Item could belong to an Item Category. Optional parameter. |

Bar Code | Field represents the bar code of the inventory to generate the specific bar code wise report. |

Requires Lot Management | This is the check box, when the check box is active, report will show the only inventory which require lot management is active. |

Last Acquisition Date | System allows to insert the begging and end inventory acquisition date. |

Last Count Date | System allows to insert the begging and end inventory count date. |

Tag Barcodes Of Storage Bins Report

Overview

Display report for the tag of the bar code corresponding to the Storage Bin.

Navigation

Inventories ► Reports ► Tag Barcodes of Storage Bins Report

Tag Barcodes of Storage Bins Report Filter Fields

Field | Description |

Type of Barcode | Field represents the bar code type of inventory. |

Warehouse | Warehouse ID where the Inventory Items are stored. Optional parameter. |

| Row | Storage Bin Row, Optional filter critea for Tag Barcodes of Storage Bins Report. |

| Stack | Storage Bin Stack, Optional filter critea for Tag Barcodes of Storage Bins Report. |

| Level | Storage Bin Level, Optional filter critea for Tag Barcodes of Storage Bins Report. |

Item Class Stack | Inventory Item could belong to a Catalogue Item, also a Catalogue Item could belong to an Item Class. Optional parameter. |

Catalogue Item | Catalogue Item ID of the Inventory Item. Optional parameter. |

Catalogue Item Category | Inventory Item could belong to a Catalogue Item, also a Catalogue Item could belong to an Item Category. Optional parameter. |

Bar Code | Field represents the bar code of the inventory to generate the specific bar code wise report. |

Storage Bin Type | Field contains the Storage Bin Type. If users want to generate report for any Storage Bin Type, users need to select the Storage bin Type from dropdown. |

Storage Unit Type | Field contains the storage unit type. If users want to generate report for any Storage Unit Type, users need to select the Storage Unit Type from dropdown. |

| Storage Section | Storage Section ID, Optional filter criteria for Tag Barcodes of Storage Bins Report. |

Valuation Reports

Valuation By Institution Report

Overview

This report displays the Current Inventory Total value for all the Warehouses belonging to an Institution. It includes a list of all Warehouses with associated Inventory Total Cost.

Navigation

Inventories ► Reports ► Valuation Reports ► Valuation by Institution

Valuation by Institution Report Filter Fields

Field | Description |

Institution | Users can look up and select an Institution as filter criteria for the Valuation by Institution Report. |

Sort By | Click the “Move Selected Item”, “Move All Item”, “Remove Selected Item”, “Remove All Item” icons to add and remove filter criteria to / from the selected list and click the “Move Selected Item to Top of List”, “Move Selected Item up one in List”, “Move Selected Item down one in List”, “Move Selected Item to Down of List” icons to move the items in the selected list up and down to put them in the desired order of appearance. |

Warehouse ID | By the preferred ascending and descending order using the Red Arrow icons. |

Valuation By Warehouse Report

Overview

This report displays the Current Inventory Total value of all the Item Categories or Item Classes within a Warehouse.

Navigation

Inventories ► Reports ► Valuation Reports ► Valuation by Warehouse

Valuation by Warehouse Report Filter Fields

Field | Description |

Group By | Indicates how the items within the report is grouped, either ‘Item Category’ or ‘Item Class’. |

Institution | Users can look up and select an Institution as filter criteria for the Valuation by Warehouse Report. |

Warehouse | Users can look up and select a Warehouse as filter criteria for the Valuation by Warehouse Report. |

Sort By | Click the “Move Selected Item”, “Move All Item”, “Remove Selected Item”, “Remove All Item” icons to add and remove filter criteria to / from the selected list and click the “Move Selected Item to Top of List”, “Move Selected Item up one in List”, “Move Selected Item down one in List”, “Move Selected Item to Down of List” icons to move the items in the selected list up and down to put them in the desired order of appearance. |

Category ID | By the preferred ascending and descending order using the Red Arrow icons. |

Other Reports

Catalogue Item Classification List

Overview

This report shows the Classification List of the Catalogue Item. It can be by Category or Class because the system has these two types of classification. The report contains the following information of each Classification Item: ID, Name, and Level. The report can be filtered by Level, this allows to the user to choose until what level he/she wants to include in the report.

An example of the report is shown below.

Navigation

Definition of Report Fields

The Catalogue Item Classification List Report includes the following fields:

| Report Fields | Description |

| Report Date | Date of report generation automatically generated by the system |

| Report Time | Time of report generation automatically generated by the system |

| User | User who generates the report |

| Page | Page Number |

| Type | The type that the Catalogue Item Classification List Report is designated to. For example, this report is defined by category |

| Sort By | Used to sort the report by Category ID (upward) |

| Category ID | The identification number of the category |

| Category Short Description | The description of the assets in the inventory category |

| Level | The level of functions associated and attached to a hierarchy of connected items |

Generation of the Report

The Catalogue Item Classification List Report shows the Classification List of the Catalogue Item.

To GENERATE this report, follow the steps below:

Navigation

The Catalogue Item Classification List Report includes the following filter criteria available for the report:

- Group By: Select a Group By value from the drop-down menu

- Level: The level of functions associated and attached to a hierarchy of connected items

- Sort By - Click the

,

,  ,

, ,

,  icons to add and remove filter criteria to / from the selected list and click the

icons to add and remove filter criteria to / from the selected list and click the  ,

,  ,

,  ,

,  icons to move the items in the selected list up and down to put them in the desired order of appearance

icons to move the items in the selected list up and down to put them in the desired order of appearance - Sort the Catalogue ID by the preferred ascending and descending order using the red arrow icon.

If all filter criteria are left blank, all Levels will be included in the Report.

The report can be exported in HTML, PDF, MS Excel, RTF and MS Word formats, prior to printing, using the ![]() ,

,  ,

,  ,

,  , and

, and  icons.

icons.

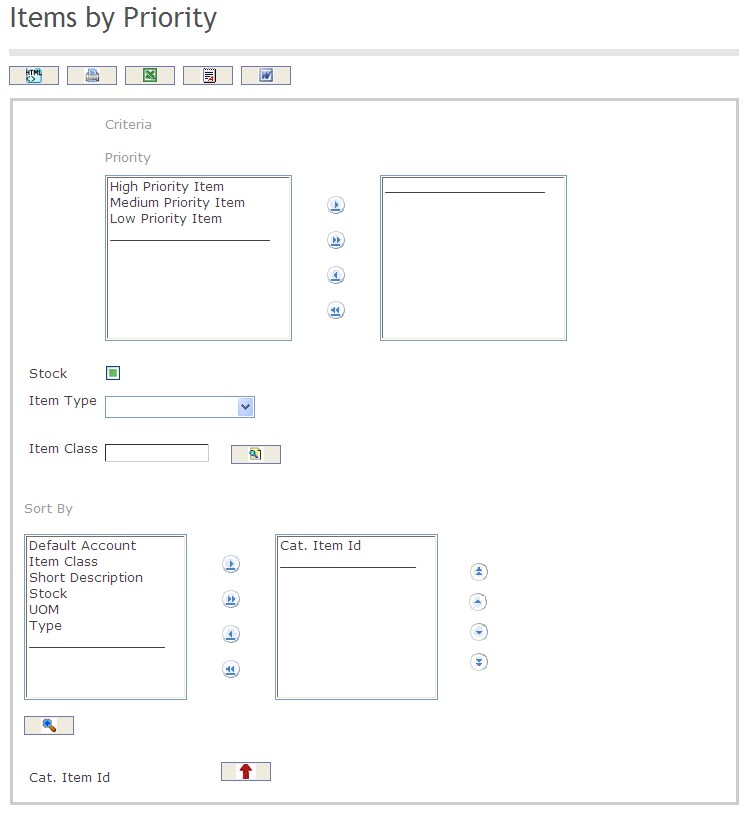

Catalogue Item By Priority

Overview

This report shows a list of the Catalogue Items grouped by Priority (High, Medium, Low). It contains the following information of each Catalogue Item: Catalogue Item ID, Item Short Description, Item Type (Good or Service), Unit of Measure – UOM, Stock Item (Yes or No), Item Class, and Default Account. The following filters are available: Priority, Item Type, Stock Item, and Item Class.

An example of the report is shown below.

Navigation

Definition of Report Fields

The Catalogue Item By Priority Report includes the following fields:

| Report Fields | Description |

| Report Date | Date of report generation automatically generated by the system |

| Report Time | Time of report generation automatically generated by the system |

| User | User who generates the report |

| Page | Page Number |

| Filter Criteria | Filter Criteria as entered under the Catalogue Item By Priority Report |

| Sort By | Used to sort the report by Priority (downward) and Catalogue ID (upward) |

| Priority | The level of importance of a specific report |

| Number of Items | The number of asset items listed in a specific report |

| Cat. Item ID | The identification number of the category item |

| Short Description | The description of the asset item |

| Type | The type of inventory item. For example, a good or a service |

| UOM | The classification for measurement of the catalogue item |

| Stock | Defines whether an inventory item is or is not in stock (Yes if in stock, No if not in stock) |

| Item Class | Defines basic characteristics of the inventory item |

| Default Account | If an element is defined in the object segment of the chart of accounts, this code will be used as part of the coding block when issuing a purchase order or purchase requisition that includes this particular item |

Generation of the Report

The Catalogue Item By Priority Report shows a list of the Catalogue Items grouped by Priority (High, Medium, Low).

To GENERATE this report, follow the steps below:

Navigation

The Catalogue Item By Priority Report includes the following filter criteria available for the report:

- Priority - Click the

,

,  ,

, ,

,  icons to add and remove priority definitions to / from the selected list.

icons to add and remove priority definitions to / from the selected list. - Stock - Click the stock checkmark to define whether the catalogue item is in stock or not in stock.

- Item Type - Select an Item Type from the drop-down menu.

- Item Class - Item Class unit (optional parameter) that can be selected using the Lookup icon

, and Find icon

, and Find icon  to retrieve the Item Class unit. If selected, the report will include the selected Item Class unit and all Item Class units below the selected unit. Refer to Item Class for more information.

to retrieve the Item Class unit. If selected, the report will include the selected Item Class unit and all Item Class units below the selected unit. Refer to Item Class for more information. - Sort By - Click the

,

,  ,

, ,

,  icons to add and remove filter criteria to / from the selected list and click the

icons to add and remove filter criteria to / from the selected list and click the  ,

,  ,

,  ,

,  icons to move the items in the selected list up and down to put them in the desired order of appearance

icons to move the items in the selected list up and down to put them in the desired order of appearance - Sort the Cat. Item ID, Short Description, Item Type, UOM, Stock, Item Class, and Default Account by the preferred ascending and descending order using the red arrow icon.

If all filter criteria are left blank, all Stocks, Item Types, and Item Classes will be included in the Report, as well as the Item Classes allowed by the report user security profile.

The report can be exported in HTML, PDF, MS Excel, RTF and MS Word formats, prior to printing, using the ![]() ,

,  ,

,  ,

,  , and

, and  icons.

icons.

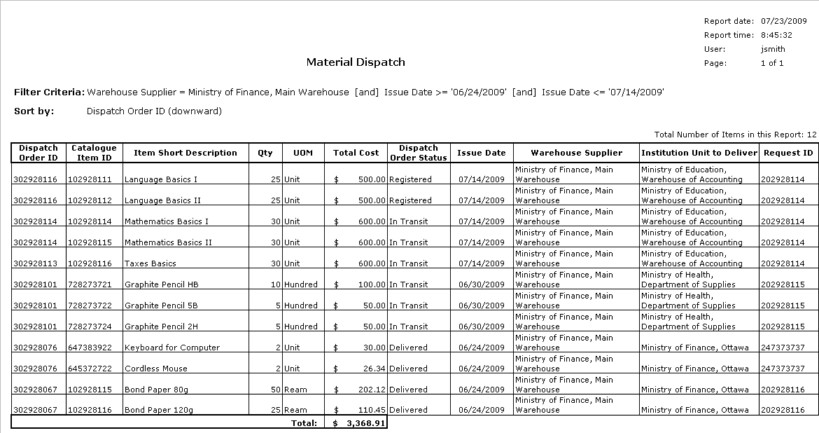

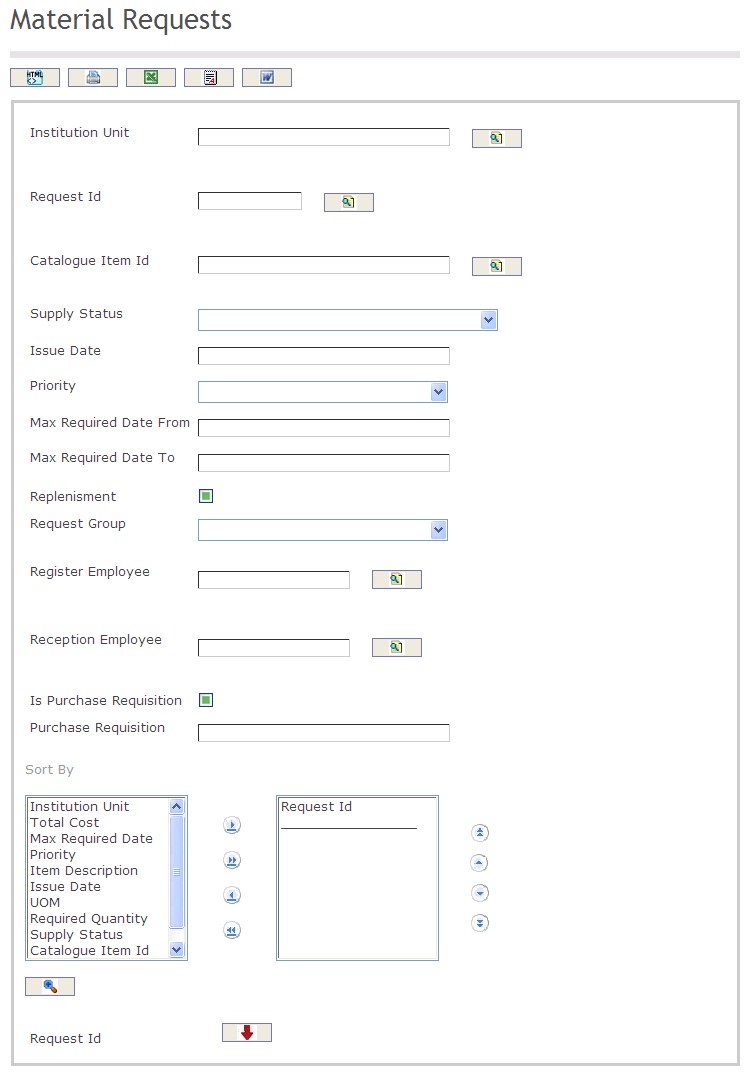

Material Request Report

Overview

This report shows a list of the Material Items requested by Institution Units. It contains information of each Requested Item such as Request ID, Catalogue Item ID, Item Short Description, Required Quantity, Total Cost, Supply Status, Issue Date, Institution Unit, etc. Some filters are available such as Institution Unit, Request ID, Catalogue Item ID, Supply Status, Issue Dates Range, Items with or without Purchase Requisitions, etc.

An example of the report is shown below.

Navigation

Definition of Report Fields

The Material Request Report includes the following fields:

| Report Field | Description |

| Report Date | Date of report generation automatically generated by the system |

| Report Time | Time of report generation automatically generated by the system |

| User | User who generates the report |

| Page | Page Number |

| Filter Criteria | Filter Criteria as entered under the Material Request Report |

| Sort By | Used to sort the report by Request ID (downward) |

| Request ID | The identification number of the Request ID |

| Catalogue Item ID | The identification number of the Catalogue Item |

| Item Short Description | The description of the items in the Material Request Report |

| Req. Qty | The required quantity of the specific item |

| UOM | The classification for measurement of the inventory item |

| Total Cost | The total cost of the inventory item |

| Supply Status | States whether the inventory item is available |

| Issue Date | The date of issue of the inventory item |

| Req. Institution Unit | The institution which will approve the inventory item order process |

| Priority | The level of importance of the inventory item in the report |

| Max Req. Date | The date that the required number of inventory items for that specific catalogue must be ordered by |

| Totals | The total monetary value of the Total Cost |

Generation of the Report

The Material Request Report shows a list of the Material Items requested by Institution Units.

To GENERATE this report, follow the steps below:

Navigation

The Material Request Report includes the following filter criteria available for the report:

- Institution Unit - Institution unit (optional parameter) that can be selected using the Lookup icon

, and Find icon

, and Find icon  to retrieve the Institution unit. If selected, the report will include the selected Institution unit and all Institution units below the selected unit. Refer to Institutions for more information.

to retrieve the Institution unit. If selected, the report will include the selected Institution unit and all Institution units below the selected unit. Refer to Institutions for more information. - Request ID - Request ID unit (optional parameter) that can be selected using the Lookup icon

, and Find icon

, and Find icon  to retrieve the Request ID unit. If selected, the report will include the selected Request ID unit and all Request IDs below the selected unit. Refer to _________ for more information.

to retrieve the Request ID unit. If selected, the report will include the selected Request ID unit and all Request IDs below the selected unit. Refer to _________ for more information. - Catalogue Item ID - Catalogue Item ID unit (optional parameter) that can be selected using the Lookup icon

, and Find icon

, and Find icon  to retrieve the Catalogue Item ID unit. If selected, the report will include the selected Catalogue Item ID unit and all Catalogue Item IDs below the selected unit. Refer to Catalogue Item for more information.

to retrieve the Catalogue Item ID unit. If selected, the report will include the selected Catalogue Item ID unit and all Catalogue Item IDs below the selected unit. Refer to Catalogue Item for more information. - Supply Status - Select a supply status from the drop-down menu.

- Issue Date From - Enter the Issue Date From (optional parameter) that can be selected by using the calendar icon

- Issue Date To - Enter the Issue Date To (optional parameter) that can be selected by using the calendar icon

- Priority - Select a priority from the drop-down menu. Choices include High, Low, and Medium

- Max Required Date From - Enter the Max Required Date From (optional parameter) that can be selected by using the calendar icon

- Max Required Date To - Enter the Max Required Date To (optional parameter) that can be selected by using the calendar icon

- Replenishment - Replenishment Status - if checked, the report will be replenished.

- Request Group - Select a request group from the drop-down menu.

- Register Employee - Register Employee unit (optional parameter) that can be selected using the Lookup icon

, and Find icon

, and Find icon  to retrieve the Register Employee unit. If selected, the report will include the selected Register Employee unit and all Register Employees below the selected unit. Refer to Employee for more information.

to retrieve the Register Employee unit. If selected, the report will include the selected Register Employee unit and all Register Employees below the selected unit. Refer to Employee for more information. - Reception Employee - Reception Employee unit (optional parameter) that can be selected using the Lookup icon

, and Find icon

, and Find icon  to retrieve the Reception Employee unit. If selected, the report will include the selected Reception Employee unit and all Reception Employees below the selected unit. Refer to Employee for more information.

to retrieve the Reception Employee unit. If selected, the report will include the selected Reception Employee unit and all Reception Employees below the selected unit. Refer to Employee for more information. - Is Purchase Requisition - if checked, purchase requisition is enabled.

- Purchase Requisition - Enter the purchase requisition information in the space provided.

- Sort By - Click the

,

,  ,

, ,

,  icons to add and remove filter criteria to / from the selected list and click the

icons to add and remove filter criteria to / from the selected list and click the  ,

,  ,

,  ,

,  icons to move the items in the selected list up and down to put them in the desired order of appearance

icons to move the items in the selected list up and down to put them in the desired order of appearance - Sort the Request ID, Catalogue Item ID, Item Description, Required Quantity, UOM, Total Cost, Supply Status, Issue Date, Institution Unit, Priority, and Max Required Date by the preferred ascending and descending order using the Red Arrow icon.

If all filter criteria are left blank, all Institution Units, Request IDs, Catalogue Item IDs, Status Supplies, Issue Date From, Issue Date To, Max Required Date From, Max Required Date To, Replenishments, Request Groups, Register Employees, Reception Employees, and Purchase Requisitions will be included in the Report, as well as the Institution Units, Request IDs, Catalogue Item IDs, Register Employees and Reception Employees allowed by the report user security profile.

The report can be exported in HTML, PDF, MS Excel, RTF and MS Word formats, prior to printing, using the ![]() ,

,  ,

,  ,

,  , and

, and  icons.

icons.

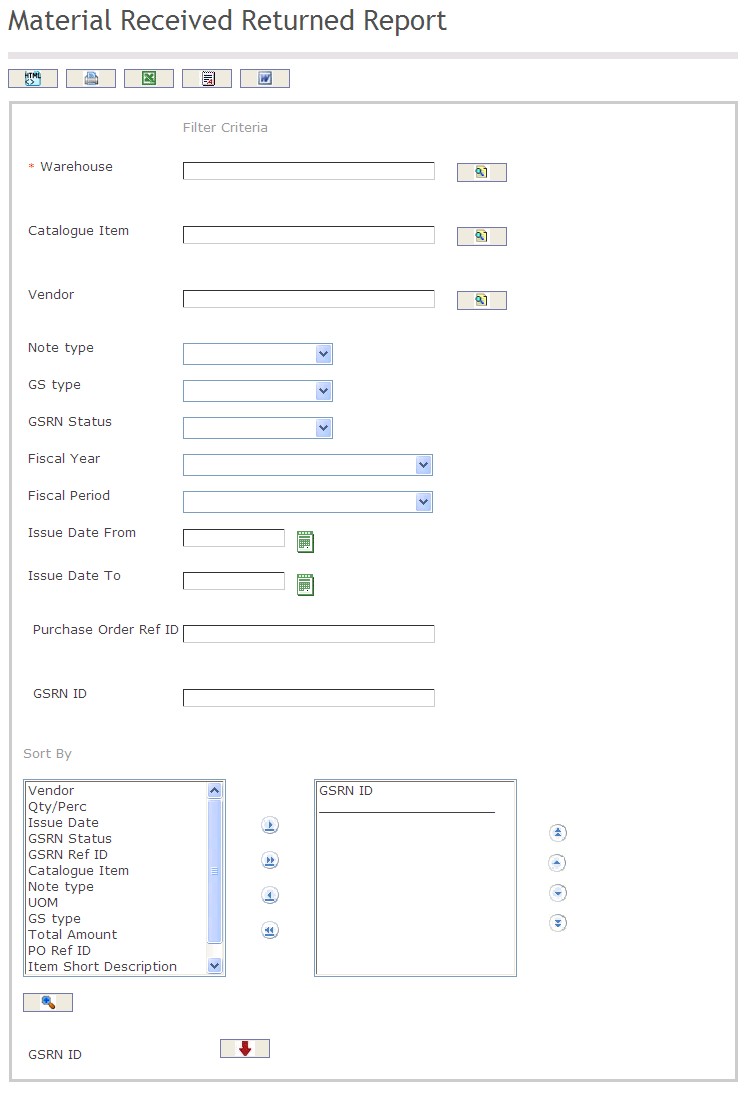

Material Received Returned

Overview

Material Received Returned includes a list of the Material Items received/returned by an Institution Unit. It contains information of each Item Received/Returned such as Good/Service Received Note (GSRN) ID, Note Type (Receive or Return), GS Type (Good or Service), Catalogue Item, Item Short Description, Quantity, Total Cost, Vendor, Purchase Order (PO) Ref ID, etc.

An example of the report is shown below.

Navigation

Definition of Report Fields

Material Received Returned Report includes the following fields:

| Report Fields | Description |

| Report Date | The date the report was created |

| Report Time | The time the reports was created |

| User | The person creating the report |

| Page | Represents the number of pages the report has |

| Filter Criteria | Filter Criteria as entered under Asset Valuation Report |

| Sort By | Describes how the report is ordered (i.e. GSRN ID (downward)) |

| GSRN ID | Good/Service Received Note unique identification number |

| Note Type | Receive or Return |

| GS Type | Refers to the Good or Service type |